Fabrication

Our state-of-the-art fabrication facility is equipped to deliver high-precision, heavy-duty fabrication solutions tailored for industries such as Power Generation, Cement, oil & gas, mineral processing, and heavy engineering. With advanced machinery, skilled personnel, and strict quality controls, we provide end-to-end fabrication services including machining, up to six meter length pipe rolling, automatic and manual welding, and laser cutting.

1. Machining Capabilities

Our machine shop is outfitted with modern machines with turning diameter up to two meters to ensure precision in component finishing.

Key Equipment :

- NC turning centers

- Horizontal boring machine

- Radial drilling machines up to 2.5 Mtr. arm lenth.

- Surface grinders.

Services :

- Precision turning and boring

- Threading and facing

- Machining of large components (up to 2 Mtr. diameter).

- Tolerance accuracy as per ISO and ASME standards

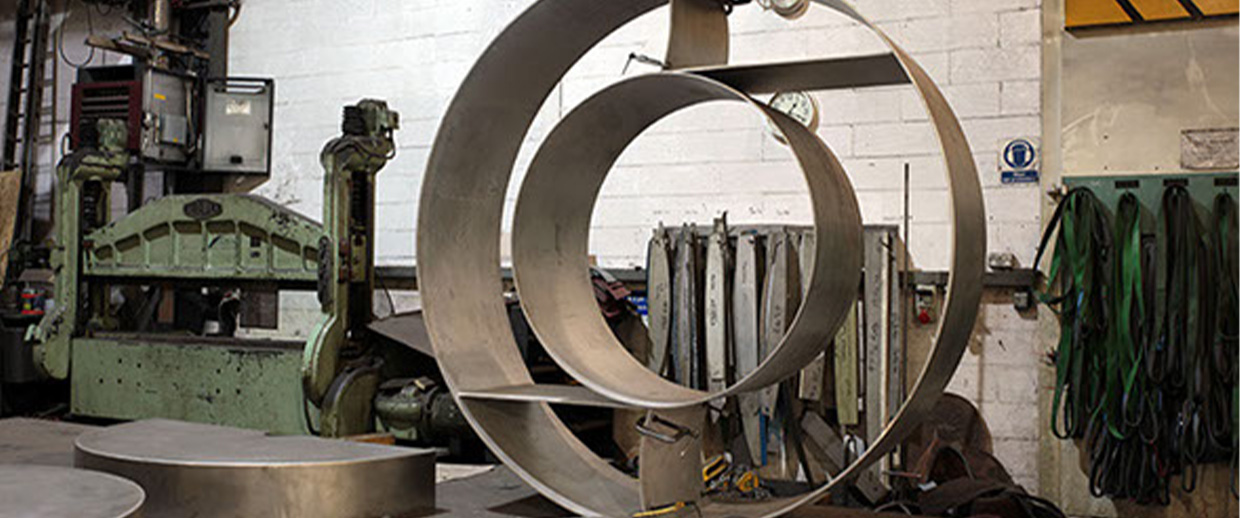

2. Pipe Rolling and Bending

We specialize in rolling of pipes and plates up to six meter single length to meet custom radius and diameter specifications for industrial piping and pressure vessels.

Capabilities:

- Rolling of carbon steel, stainless steel, and alloy steel pipes

- Pipe diameters from [400 mm to 2 Mtr], wall thickness up to 35 mm.

- CNC-controlled pipe bending for tight radius and complex geometries

- Plate rolling up to 35 mm thick.

Applications include Coal Mill Body and internals along with stainless steel ducting systems.

3. Welding and Fabrication

Welding is a core strength of our fabrication services, carried out by qualified welders in accordance with international codes (ASME, AWS, EN).

Welding Processes :

- SMAW (Shielded Metal Arc Welding)

- GMAW/MIG (Gas Metal Arc Welding)

- SAW (Submerged Arc Welding)

Highlights :

- Welding of Carbon Steel and Stainless Steel materials

- Certified welders and WPS/PQR documentation

- Pre-heating, post-weld heat treatment (PWHT) facilities

- In-house NDT inspection (UT, RT, MPI, DPI)

4. Cutting Facilities

We utilize high-precision cutting technologies to ensure clean edges, accurate dimensions, and minimal material waste.

Cutting Technologies :

- CNC plasma cutting

- Oxy-fuel cutting

- Laser cutting (for precision sheet metal work)

- Hydraulic shearing

Capabilities :

- Plate cutting up to [ 40 mm thickness]

- Cutting for structural steel, pressure parts, and custom profiles

- Template and contour cutting for custom fabrication

5. Facility Infrastructure

- Covered Shop Floor Area: [50000 sq. ft.] + 40000 sq feet + 35000 sq Feet.

- Material Handling: Overhead cranes (up to 5 tons), forklifts, mobile cranes

- Power Backup: Diesel generators to ensure uninterrupted operations

- Layout: Segregated bays for machining, welding, rolling, and final assembly

6. Quality Assurance

We maintain a robust quality management system supported by:

- ISO 9001:2015 certification

- In-house inspection team and third-party inspection (TPI) support

- Material traceability and documentation

- Calibrated measuring instruments and testing tools

7. Safety and Compliance

Safety is integral to our operations:

- Regular training and PPE for staff

- Fire protection systems and emergency response protocols

- Compliance with OSHA, local labor laws, and environmental guidelines